Defoamers for Phosphoric Acid Production

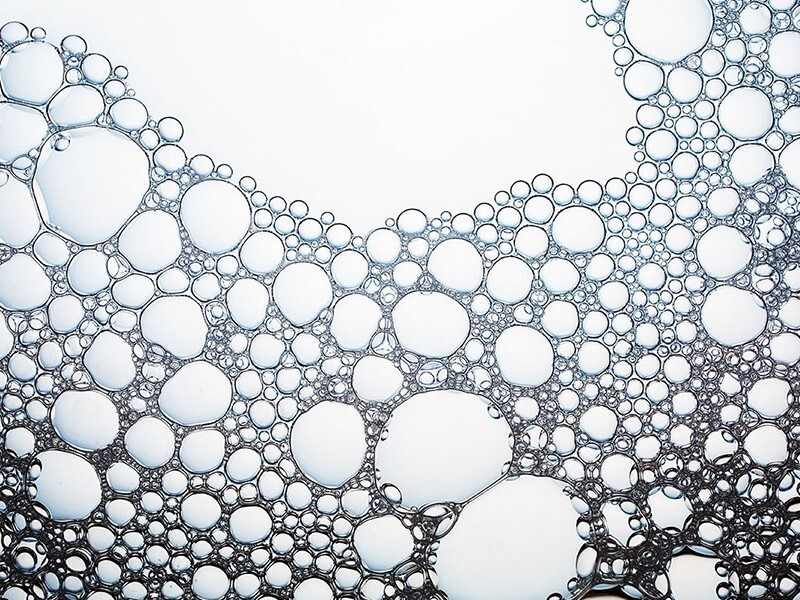

The entrained gases diminish the pumping efficiency of the system, and the foam itself takes up valuable head space in the reactors, effectively reducing production capacity. Both problems wreak havoc on the designed process parameters of the system, which can result in more rapid scale formation in piping and plugging of filter media, both of which can lead to more shutdowns. When excess entrained gas and foam cause problems with sulfate control in the reaction due to poor circulation, there can also be losses of the valuable P2O5, partly due to poor gypsum crystal formation, which reduces acid filtration rates.

One of the major challenges that phosphoric acid producers face in achieving desired plant production rates and efficiencies is identifying the optimal means of removing such gases that are liberated during these production processes. Mechanical equipment can be added to plants for this purpose but is capital-intensive to install, equally expensive to maintain, and provides only a partial solution at best. Process chemical additives such as defoamers have become the universally accepted “best practice” alternative for accelerating the removal of unwanted gases and improving plant performance.

One of the major challenges that phosphoric acid producers face in achieving desired plant production rates and efficiencies is identifying the optimal means of removing such gases that are liberated during these production processes. Mechanical equipment can be added to plants for this purpose but is capital-intensive to install, equally expensive to maintain, and provides only a partial solution at best. Process chemical additives such as defoamers have become the universally accepted “best practice” alternative for accelerating the removal of unwanted gases and improving plant performance.

Arkema defoamers maximize the removal of these gases and their undesirable influence on phosphoric acid production processes by reducing the surface tension on the gas bubble surface. We have a long history of supplying products to the phosphate industry, and it remains a critical strategic focus for us today. That focus has led us to develop an extensive range of defoamers customized for our customers' specific operating and raw material conditions.

Arkema's broad range of defoamers are designed with multiple functionalities to ensure that the defoamers:

Arkema's broad range of defoamers are designed with multiple functionalities to ensure that the defoamers:

- Remain functional within phosphoric acid reactors for long periods without breaking down. This provides degassing performance of entrained gases that continues through multiple cycles of reaction, filtration, and recycled acid flow.

- Quickly go into solution in the phosphoric acid within the reactors, providing immediate results in breaking surface foam. They also have the added benefit of being more cost-effective if the foam problem is less severe or is a surface issue only.

- Exist longer in a phosphoric acid medium. Our specialty defoamers perform exceptionally well in rubber-lined evaporators and fertilizer scrubber systems and do not da

Benefits

Improved capacity utilization and yield- Improved reaction and filtration efficiency

Increased recovery of raw materials due to lower losses in scrubbers, flash coolers, and evaporators

Improved calcium sulfate crystallization and lower unit cost by improving plant rates

Lower maintenance spending on mechanical gas removal equipment

Reduced plant downtime

Reduced health, and safety issues as a result of lower fugitive emissions

More information about this range: Defoamers for Phosphoric Acid Production

Quell® 516

Control foam formation during the wet process

• Increased capacity utilization

• Improved yields & reduced losses

• Better recirculation