Chemical Solutions to Improve Low Density Ammonium Nitrate Product Quality and Performance

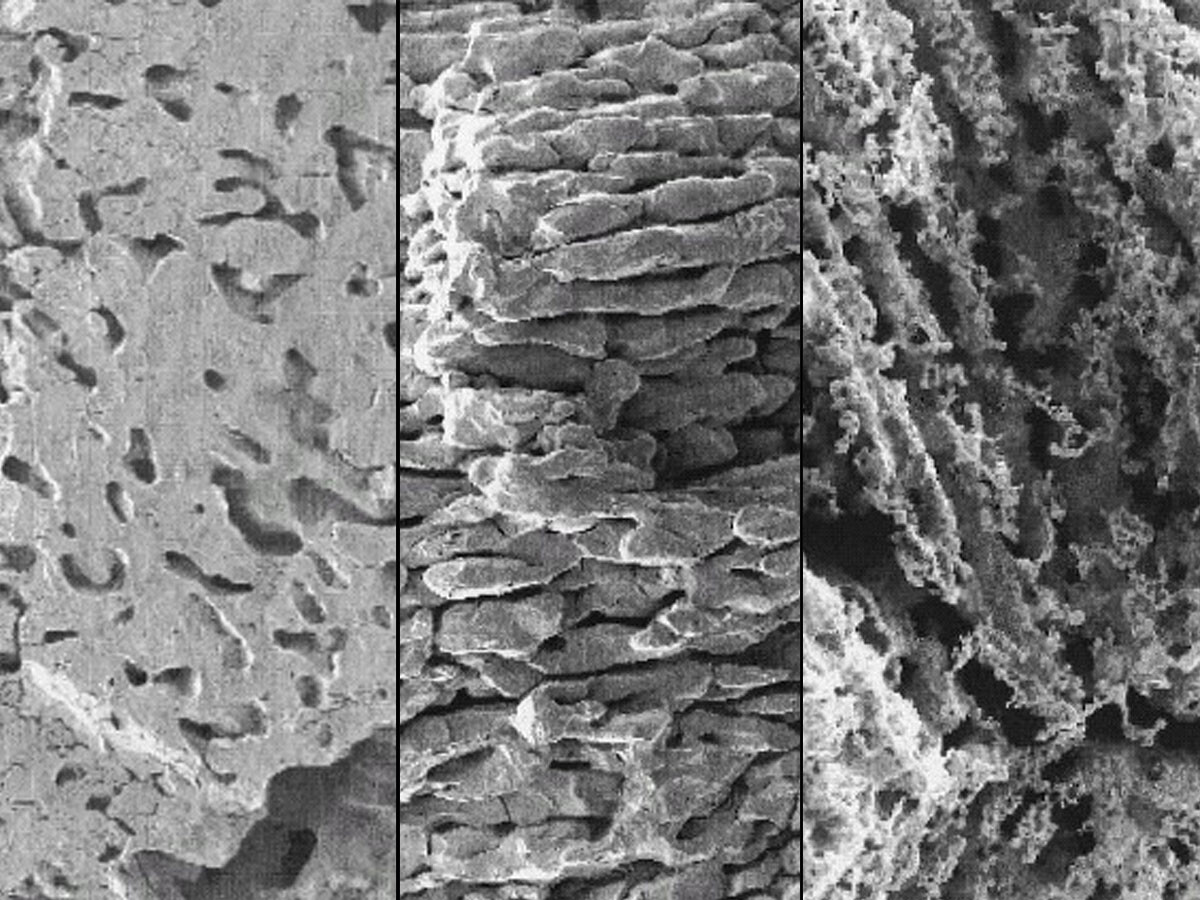

Explosive grade ammonium nitrate/LDAN/IGAN has specific quality parameters that must be met. Porosity is critical for good oil absorption but should not weaken the prill. Arkema’s porosity control agents cover a range of applications. They have been developed for specifics such as the spinning bucket process (reduction of foam generated during the low-density ammonium nitrate production process).

Our Galoryl® anti-caking agents are specifically formulated for use on porous prilled ammonium nitrate to prevent ingress of oily components from either the “active” or the “carrier” components into the prill and causing it to soften. Maintaining quality control parameters, such as density and porosity, is critical for oil absorption and prill hardness and, ultimately, the final performance of the prill.

Arkema’s expertise in global markets and explosives development means that we are well-equipped to actively work with our customers on custom design products that meet their unique low-density ammonium nitrate (LDAN/IGAN) requirements.

Benefits

- Free-flowing prill for improved performance in underground or surface applications

- Reduced moisture and better thermocycle stability

- Improved uptake of liquid fuel oil

- Uniform fuel absorption to enhance reactivity

- Ideal detonation behavior and superior field performance

- Minimized caking tendencies

- Reduced attrition during handling and storage