Sustainable Surfactants for High-Performance Industrial Formulations

Sustainability is at the heart of our development

For the world to change, we need to change the materials we use. To achieve a more sustainable future, Arkema is committed to being a top performer as a responsible manufacturer, driving change through sustainable solutions, and maintaining open dialogue with our stakeholders to create value for all.

At Specialty Surfactants, our strategy is grounded in Arkema’s sustainability pillars and includes in particular the respective three core values: Expertise, Safety and Efficiency. These values fuel our drive for innovation, guide our commitment to safety, and optimize our use of resources for the benefit of our customers.

Our Three Core Values

-

EXPERTISE

Since 2015, 80% of Arkema Specialty Surfactants' patents each year have focused on enhancing sustainability for our customers. Our commitment to sustainable innovation has received international recognition, including the Potier Prize in 2007, the International Road Federation Prize in 2008, the ICIS Best Innovation and Best Product Prize in 2009, the L’Usine Nouvelle Prize in 2020, and the ICIS Prize in 2021.

-

SAFETY

Safety is integral to every process, ensuring rigorous standards that protect people and the environment. However, safety is also about supply. Depending on the application and market needs, we integrate up to 100% bio-sourced raw materials, reinforcing our dedication to reducing environmental impact.

-

EFFICIENCY

Efficiency guides our operations. We have plans in place at our production sites to optimize the use of resources, water, and energy. We also intend to preferentially use locally sourced raw materials according to our customers' quality demands. Through open dialogue with your teams, our local laboratories carefully select locally sourced raw materials (making up more than 75% of the volume) and optimize customers’ processes and products.

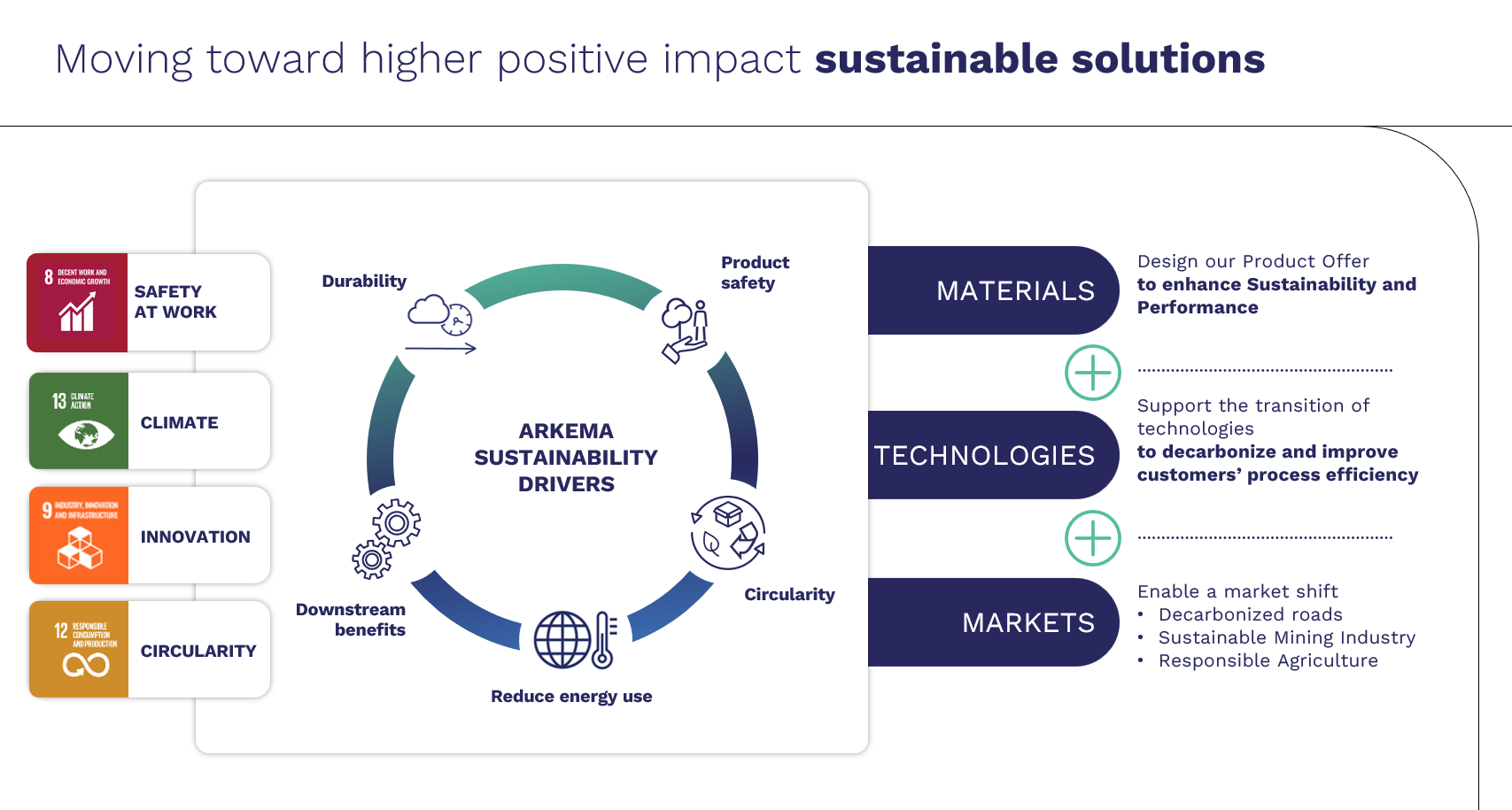

Moving toward sustainable solutions with higher positive impact

From Commitment to Concrete Impact: applications and use-cases

Production efficiency for the Mining industry

We offer a wide range of froth flotation reagents to enhance mineral processing. We have designed a new generation of collectors to address economic challenges and supply and demand imbalances. In lithium extraction, these increase yields by 2 to 6% compared with traditional chemicals, with a key focus on reducing costs per ton of concentrate produced.

We offer a wide range of froth flotation reagents to enhance mineral processing. We have designed a new generation of collectors to address economic challenges and supply and demand imbalances. In lithium extraction, these increase yields by 2 to 6% compared with traditional chemicals, with a key focus on reducing costs per ton of concentrate produced.

Reduce energy use in Road construction

The transition from traditional Hot Mix Asphalt (HMA) to Warm Mix Asphalt (WMA) is a revolutionary advance in the road construction.

The transition from traditional Hot Mix Asphalt (HMA) to Warm Mix Asphalt (WMA) is a revolutionary advance in the road construction.

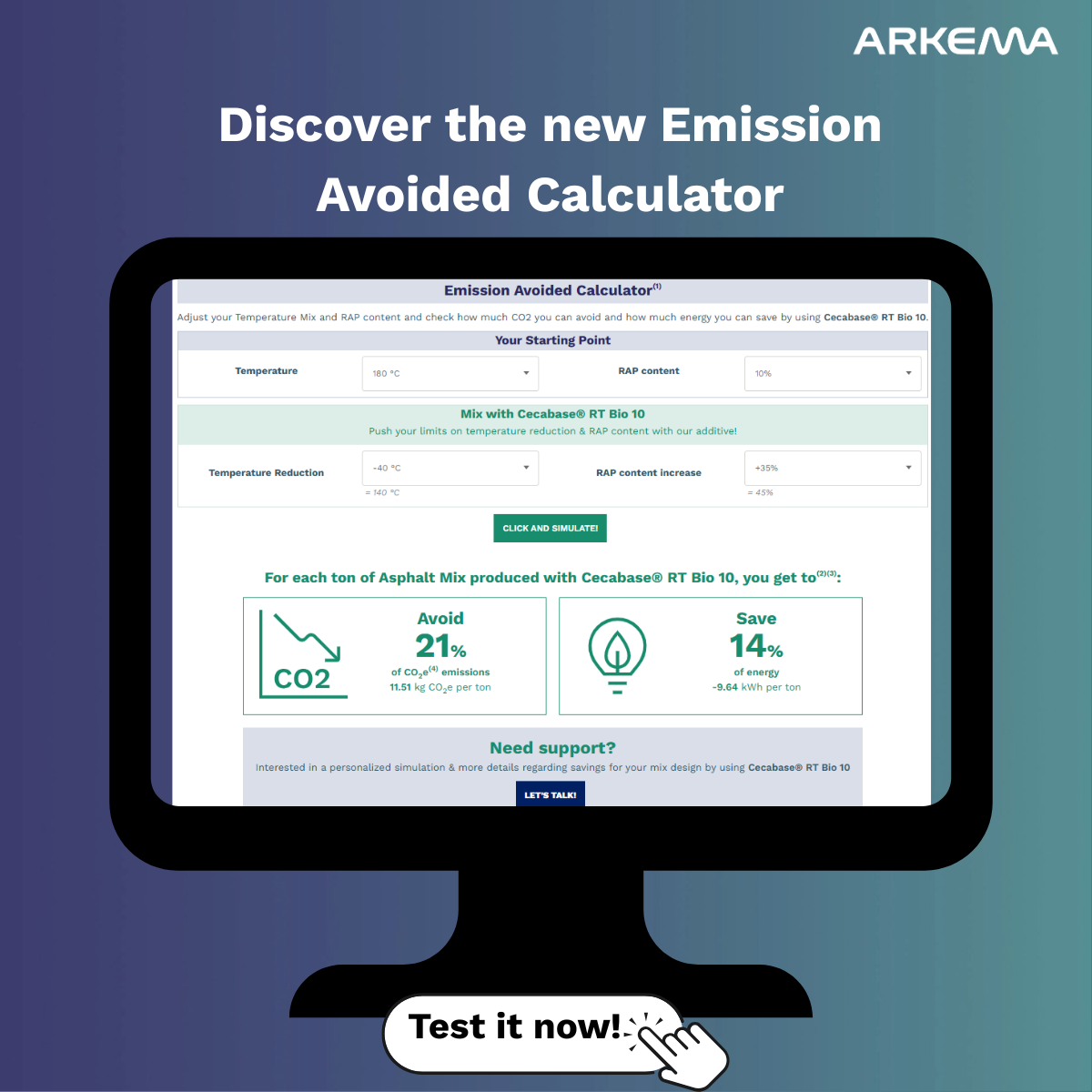

In an era where we need to introduce more recycled resources and keep products in use longer, our proven Warm Mix technology and additives since 2007 allow to increase the recycling content up to 50%, and to lower the production and compaction temperatures by up to 40°C, reducing accordingly energy consumption and VOC emissions. To have concrete figures to share, we developed a digital tool to assess these gains more precisely and calculate the emissions avoided by using Cecabase® RT Bio 10.

Discover our Asphalt & bitumen solutions

Contributing to circular economy with renewable content in Ethoxylated Surfactants for detergency

We offer a complete range of Non-ionic Surfactants designed to address modern cleaning challenges. Our surfactants contain between 25% and 60% of biobased ingredients (based on a carbon (EN16640 or ASTM D6866) or a mass (EN16785-2) ratio) . This renewable share can even be increased with incorporation of mass balance bio-attributed ethylene oxide. This approach reduces fossil feedstock inputs and enhances also the corresponding product carbon footprint.

We offer a complete range of Non-ionic Surfactants designed to address modern cleaning challenges. Our surfactants contain between 25% and 60% of biobased ingredients (based on a carbon (EN16640 or ASTM D6866) or a mass (EN16785-2) ratio) . This renewable share can even be increased with incorporation of mass balance bio-attributed ethylene oxide. This approach reduces fossil feedstock inputs and enhances also the corresponding product carbon footprint.