Arkema's Path to Warm Mix

Welcome to the future of asphalt pavement with ”True” WMA. Adopting this sustainable pavement technology has never been easier and represents a monumental shift in how we approach asphalt paving. With WMA, we're transforming traditional methods into innovative solutions that enhance workability, reduce environmental impacts, and elevate pavement performance to unprecedented levels.

WMA is more than just a technological advancement—it's a revolution in paving that provides the flexibility and efficiency modern infrastructure demands. By significantly lowering the production and application temperatures, WMA offers numerous advantages: it facilitates easier handling and compaction, extends the paving season even in cooler climates, and contributes to a more sustainable construction process.

The adoption of WMA is a leap forward in reducing greenhouse gas emissions and fuel consumption, addressing the urgent need for eco-friendly construction practices. This technology not only aligns with global sustainability goals but also delivers practical benefits, including longer pavement lifespans and reduced maintenance requirements.

Imagine paving projects that are quicker, more adaptable, and kinder to the environment—WMA makes this possible. It's the smart choice for those committed to innovation and environmental stewardship. Join us in embracing WMA and be at the forefront of a movement that is reshaping the future of road construction, one sustainable mile at a time.

WMA is an advanced technology for asphalt pavement designed to be produced and applied at significantly reduced temperatures compared with traditional Hot-Mix Asphalt (HMA) technology. Of course, temperature reduction is just one piece of the equation—having a dependable, effective warm-mix additive is critical for a full transition to this technology.

Effective pavement construction ensures road surfaces have the longevity and performance demanded by today’s roadway needs. Critical parameters such as density, moisture damage prevention, crack resistance, and workability during paving must be met to meet agency and local needs broadly. Doing all of these while reducing temperature creates a more complicated set of considerations when producing asphalt mixtures and paving on jobs.

Arkema’s WarmGrip® warm mix additives are at the forefront of this technological evolution. These additives serve as compaction aids and trusted adhesion promoters, making producing and compacting asphalt mixes at reduced temperatures more straightforward. By lowering the production and application temperatures, these additives help safeguard against moisture-related issues such as potholes and rutting, which can significantly degrade pavement quality.

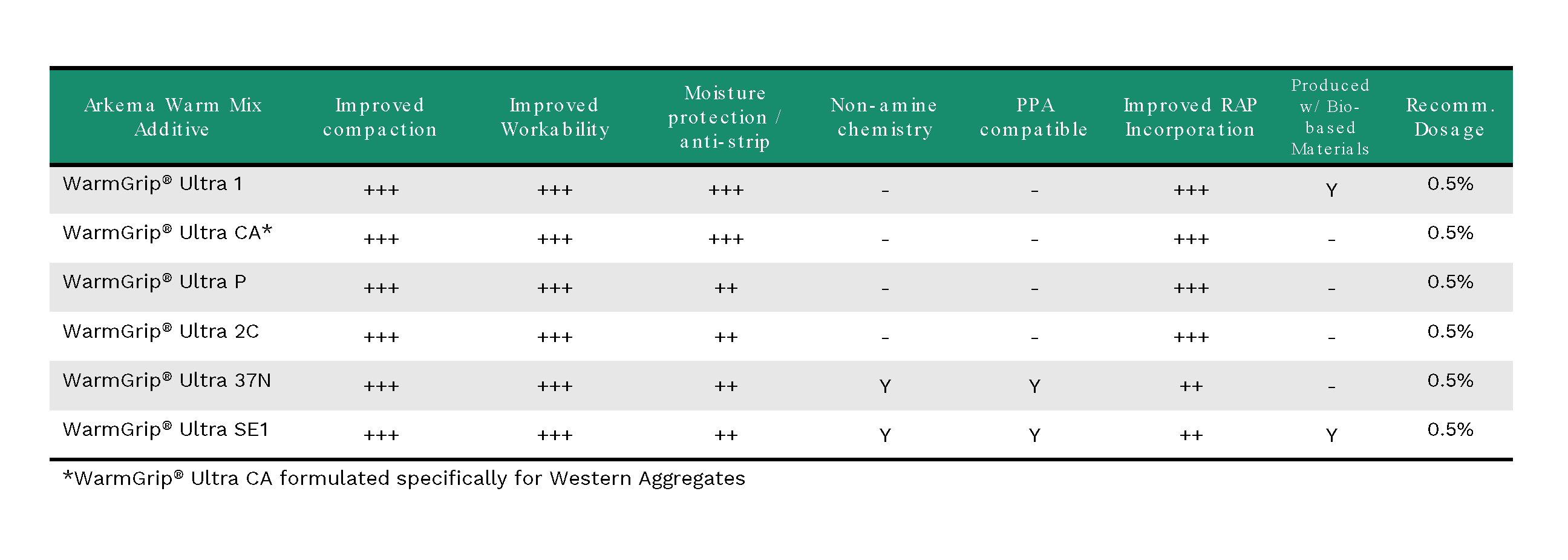

The WarmGrip® product lines are purposely engineered to meet diverse customer requirements, offering features like PPA (Polyphosphoric Acid) compatibility for enhanced performance, low viscosity for easier handling, and options that are odorless and smoke-free, ensuring a safer and more pleasant working environment. These additives not only facilitate superior compaction but also contribute to the overall sustainability of pavement projects by reducing emissions and energy consumption during the asphalt production process.

Take the opportunity to reduce your carbon footprint, optimize energy consumption, and enhance the durability of your pavement solutions. Arkema’s patented warm mix additive technology, a game-changer in the industry, will elevate your WMA performance. Join the Warm Mix Revolution and partner with Arkema and WarmGrip® warm mix additives to lower your temperatures and drive more sustainable solutions. Together, we can build a brighter, more resilient future.

|

WarmGrip® ULTRA 1 |

WarmGrip® ULTRA CA |

WarmGrip® ULTRA 2C |

|

WarmGrip® ULTRA SE1 |

WarmGrip® ULTRA P |

WarmGrip® ULTRA 37 |