Join the Warm Mix Revolution

Arkema's Path to Warm Mix

Welcome to the future of asphalt pavement with ”True” WMA. Adopting this sustainable pavement technology has never been easier and represents a monumental shift in how we approach asphalt paving. With WMA, we're transforming traditional methods into innovative solutions that enhance workability, reduce environmental impacts, and elevate pavement performance to unprecedented levels.

WMA is more than just a technological advancement—it's a revolution in paving that provides the flexibility and efficiency modern infrastructure demands. By significantly lowering the production and application temperatures, WMA offers numerous advantages: it facilitates easier handling and compaction, extends the paving season even in cooler climates, and contributes to a more sustainable construction process.

The adoption of WMA is a leap forward in reducing greenhouse gas emissions and fuel consumption, addressing the urgent need for eco-friendly construction practices. This technology not only aligns with global sustainability goals but also delivers practical benefits, including longer pavement lifespans and reduced maintenance requirements.

Imagine paving projects that are quicker, more adaptable, and kinder to the environment—WMA makes this possible. It's the smart choice for those committed to innovation and environmental stewardship. Join us in embracing WMA and be at the forefront of a movement that is reshaping the future of road construction, one sustainable mile at a time.

WMA is an advanced technology for asphalt pavement designed to be produced and applied at significantly reduced temperatures compared with traditional Hot-Mix Asphalt (HMA) technology. Of course, temperature reduction is just one piece of the equation—having a dependable, effective warm-mix additive is critical for a full transition to this technology.

Effective pavement construction ensures road surfaces have the longevity and performance demanded by today’s roadway needs. Critical parameters such as density, moisture damage prevention, crack resistance, and workability during paving must be met to meet agency and local needs broadly. Doing all of these while reducing temperature creates a more complicated set of considerations when producing asphalt mixtures and paving on jobs.

Arkema’s WarmGrip® warm mix additives are at the forefront of this technological evolution. These additives serve as compaction aids and trusted adhesion promoters, making producing and compacting asphalt mixes at reduced temperatures more straightforward. By lowering the production and application temperatures, these additives help safeguard against moisture-related issues such as potholes and rutting, which can significantly degrade pavement quality.

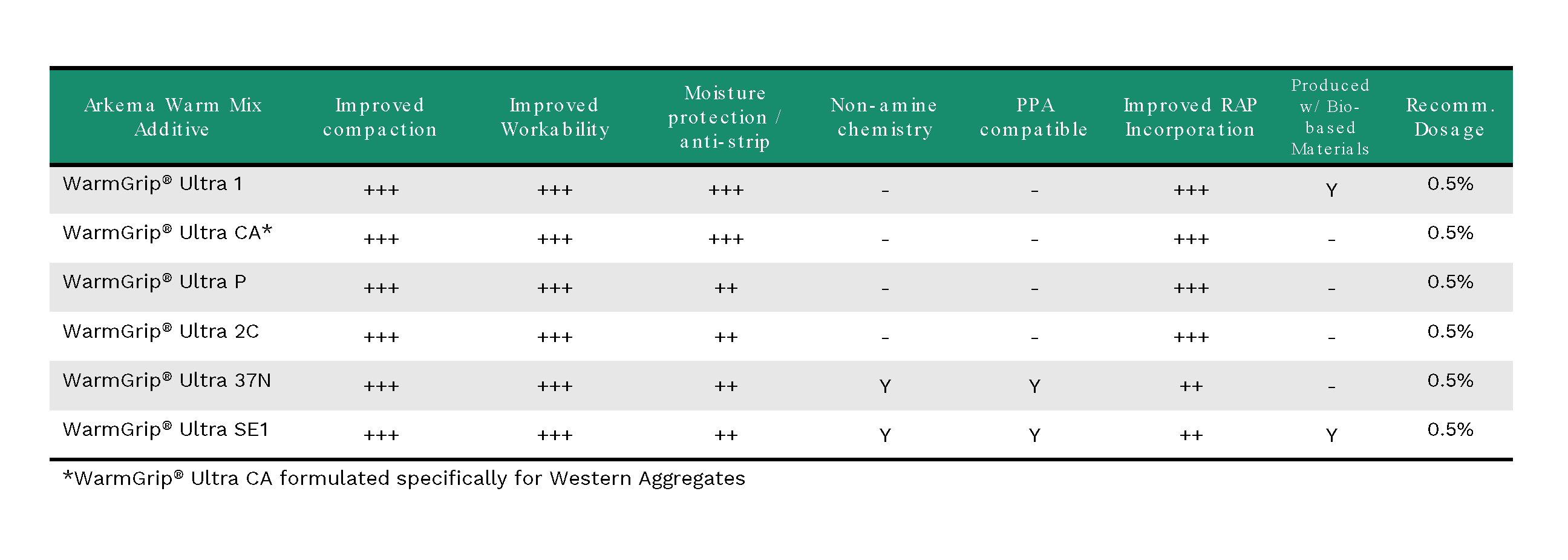

The WarmGrip® product lines are purposely engineered to meet diverse customer requirements, offering features like PPA (Polyphosphoric Acid) compatibility for enhanced performance, low viscosity for easier handling, and options that are odorless and smoke-free, ensuring a safer and more pleasant working environment. These additives not only facilitate superior compaction but also contribute to the overall sustainability of pavement projects by reducing emissions and energy consumption during the asphalt production process.

Take the opportunity to reduce your carbon footprint, optimize energy consumption, and enhance the durability of your pavement solutions. Arkema’s patented warm mix additive technology, a game-changer in the industry, will elevate your WMA performance. Join the Warm Mix Revolution and partner with Arkema and WarmGrip® warm mix additives to lower your temperatures and drive more sustainable solutions. Together, we can build a brighter, more resilient future.

|

WarmGrip® ULTRA 1 |

WarmGrip® ULTRA CA |

WarmGrip® ULTRA 2C |

|

WarmGrip® ULTRA SE1 |

WarmGrip® ULTRA P |

WarmGrip® ULTRA 37 |

Pioneering Sustainable Pavements with Warm Mix Asphalt

We are proud to announce that Boulder County, Colorado, has been honored with the 2024 NACo Achievement Award in Transportation for the Hygiene Road Construction project. This award-winning initiative highlights a significant breakthrough in sustainable road construction, showcasing the potential of Warm Mix Asphalt (WMA) as a game-changer in the industry.

In an era where environmental stewardship and efficiency are paramount, the transition from traditional Hot Mix Asphalt (HMA) to Warm Mix Asphalt (WMA) is a revolutionary step forward in the road construction industry. Boulder County, in collaboration with Arkema and Holcim Group, has successfully demonstrated the potential of WMA in a groundbreaking case study aimed at reducing the environmental impact of asphalt production.

The Boulder County case study revealed the remarkable benefits of WMA, particularly when utilizing Arkema's WarmGrip® Ultra 1 additive. By lowering the production and compaction temperatures by 45-60°F, WMA not only maintained but enhanced the quality and durability of the pavement. This reduction in temperature resulted in a significant decrease in energy consumption, emissions, and the Global Warming Potential (GWP), which saw a 12.26% reduction compared to HMA.

Key Benefits of WMA:

- Reduced Environmental Impact: Lower production temperatures led to decreased CO2 emissions and energy use.

- Enhanced Workability: Improved workability and compaction efficiency at reduced temperatures achieved without compromising quality.

- Increased Worker Safety: Elimination of blue smoke during production improved safety and comfort for workers on-site.

Success achieved in Boulder County is a testament to the power of collaboration. By working closely with industry leaders and local authorities, this initiative showcases how innovative technologies like WMA can lead to more sustainable and resilient road infrastructure.

As we move forward, the insights gained from this WMA paving project will play a critical role in shaping the future of road construction. The transition to WMA is not just an option but a necessity in our collective journey towards a Net Zero future.

Join Us in Paving the Way for a Sustainable Tomorrow

We invite industry experts, policymakers, and community leaders to embrace this revolutionary technology. Together, we can transform the road construction industry by prioritizing environmental responsibility and innovative practices.

Click here to read our NAPA Quarterly Summer 2024 article “Pioneering Sustainable Pavements: Insights from Boulder County’s Warm Mix Asphalt Trail” Link to article

Uncover the Advantages of WarmGrip® ULTRA 1

Enhance the Performance and Durability of Your Pavement

WarmGrip® ULTRA 1 is an innovative asphalt additive engineered to improve field compaction and strengthen the adhesion of asphalt binder to aggregate in warm mix asphalt. Designed to withstand the demands of heavy traffic, moisture, and oxidation, it ensures safer, smoother, and longer-lasting roads.

Key Features and Benefits:

- Improved Field Compaction: Achieve higher mat densities with lower effort, even in mixes containing high recycled asphalt pavement (RAP).

- Reliable Anti-Stripping Effectiveness: Passes anti-stripping and other performance tests across a wide variety of asphalt and aggregate combinations.

- Low Odor & Low Smoke: Formulated to minimize smoke and odor, improving comfort for both plant personnel and paving crews.

- Heat Stability: Remains effective for several weeks in hot asphalt mixtures, offering reliable performance during extended operations.

- Enables Longer Hauls: Supports longer transport distances and a wider plant coverage radius, allowing for more efficient project execution.

WarmGrip® ULTRA 1 is ideal for projects that require:

- Enhanced compaction at standard or reduced temperatures

- Passing TSR and Hamburg Wheel-Track tests, even with challenging asphalt-aggregate combinations

- Reduced smoke and odor at terminals, mix plants, or jobsites

By using WarmGrip® ULTRA 1, you safeguard your pavements against common issues like pothole formation, cracking, and rutting, leading to fewer repairs and longer road life.

Discover how WarmGrip® ULTRA 1 can improve your next asphalt project.

Contact us today to learn more about how our WarmGrip® ULTRA 1 product can meet your warm mix asphalt needs.

Discover our WarmGrip® Products

Extend Pavement Life with AD-here® LOF 65-00

Protect Your Pavements and Extend Their Lifespan

For over 25 years, AD-here® LOF 65-00 has been a trusted solution for preventing moisture damage and extending pavement life. Known for its low odor, low smoke formulation, this industry-leading liquid anti-strip additive is engineered to reduce raveling, pothole development, and rutting, ensuring safer, longer-lasting roads.

Key Features and Benefits:

-

Proven Performance Over 25 Years - A highly reliable liquid anti-strip trusted by State and Provincial Departments of Transportation (DOT) and industry stakeholders.

-

Reliable Anti-Stripping Effectiveness - Successfully passes tensile strength ratio (TSR) and Hamburg Wheel-Track tests with various asphalt and aggregate combinations.

-

Low Odor & Low Smoke - Reduces smoke and odor, ensuring better safety and comfort for plant personnel and paving crews.

-

Improves Mix Workability - Allows for easier handwork during paving applications, enhancing jobsite efficiency.

-

Heat Stability - Stays effective for several weeks in hot asphalt, offering durability and consistency in performance.

Use AD-here® LOF 65-00 when you need:

-

Proven reliability in moisture damage protection

-

Passing anti-stripping and rutting performance test results with challenging asphalt and aggregate combinations

-

Reduced smoke and odor at terminals, mix plants, and jobsites

-

Minor reductions in plant asphalt mix production temperatures

With a reputation built on quality, effectiveness, and integrity, AD-here® LOF 65-00 helps your asphalt projects meet industry standards like AASHTO T283 and T324, ensuring successful, long-lasting results.

Elevate Your Asphalt Project with AD-here® LOF 65-00

Contact us today to learn how AD-here® LOF 65-00 can improve your asphalt projects.