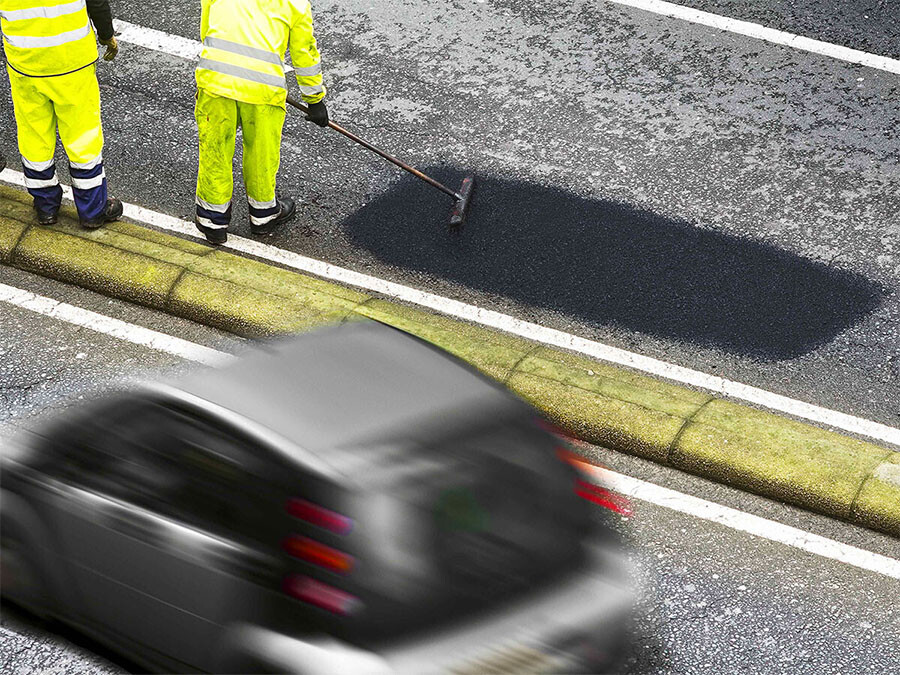

Cold Patch Mix Asphalt Additives and Adhesion Promoters

The key to better cold patch longevity and performance is the addition of the right adhesion promoter chemical, which allows the patch to displace water along the sides and bottom of the pothole and allows it to adhere correctly. Without the right adhesion promoter in the cold patch mix, the patch will not adhere well, and patch failure is imminent. Also, during patch performance, it is important that the adhesion promoter allows for proper cutback coverage on the aggregate and that it protects the cold patch from being susceptible to moisture damage after the patching mix is placed in the pothole.

Arkema manufactures cutting-edge cold mix asphalt, AD-here®, ColdGrip®, Polyram™, Stabiram® and Dinoram® for performance-improving additives and cold patch/cold mix quality and performance, enabling you to differentiate yourself from the competition.

Benefits

- Improves cold mix production efficiency

- Extends cold mix stockpile life

- Increases cold patch and pavement life

- Provides greater operational convenience

- Reduces cold mix production costs

- Improves profitability

- Enables production of low-VOC, eco-friendly cold mix

More information about this range: Cold Mix Additives

Performance improving additives

• Cold patch stockpile mix

• Eliminate stockpile stripping

• Extend life of sealer application

Easier Coating and Stronger Stripping Protection

• Longer patch and pavement life

• Easy coating of cool, wet and dusty aggregates

• Strong protection against stockpile stripping

Cationic quick and slow-setting (CQS and CSS) emulsifiers

• Liquid and easy to pump

• Good coating ability at low dosage

• Good performance with difficult aggregates