Defoamers for Fertilizer Production

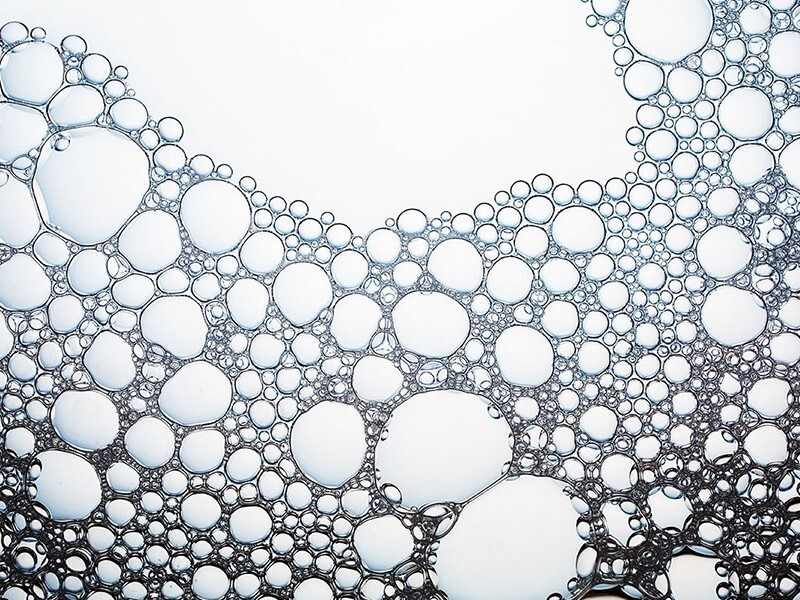

This process involves colliding a scrubber liquor with the airstream at the proper velocity to remove entrained gases and particulates. The high-speed collision traps air inside the liquid, which in turn causes a highly foamy solution that diminishes pumping efficiency and overall scrubbing capacity. If uncontrolled, it becomes a limiting factor in the output of ammonium phosphate fertilizer and risks environmental regulatory non-compliance.

An ideal granulation defoaming agent should have a superior knock-down effect on the slightly different types of surface foam bubbles in the more dilute liquid phase found in the granulation scrubbing system. Design and choice of an appropriate defoamer require an understanding of the characteristics of the phosphate rock, the particular type of granulation production processes, and the intended operating parameters.

Converting this knowledge into formulation and use of effective defoamers requires extensive experience and access to the operational and feedstock variables, which will determine the nature of the process challenge. Arkema has a long history of supplying products to the phosphate industry, and it remains a critical strategic focus today. That focus has led to the development of an extensive range of defoamer products, often customized for our customers' specific operating and raw material conditions.

An ideal granulation defoaming agent should have a superior knock-down effect on the slightly different types of surface foam bubbles in the more dilute liquid phase found in the granulation scrubbing system. Design and choice of an appropriate defoamer require an understanding of the characteristics of the phosphate rock, the particular type of granulation production processes, and the intended operating parameters.

Converting this knowledge into formulation and use of effective defoamers requires extensive experience and access to the operational and feedstock variables, which will determine the nature of the process challenge. Arkema has a long history of supplying products to the phosphate industry, and it remains a critical strategic focus today. That focus has led to the development of an extensive range of defoamer products, often customized for our customers' specific operating and raw material conditions.

Benefits

- Increased capacity utilization

Improved yields

Reduced plant downtime

Environmental stewardship from reduction of fugitive fuming

Easier regulatory compliance

More information about this range: Defoamers for Fertilizer Production

Quell® 808

Improves operational efficiency

• Improved yields & reduced losses

• Better recirculation

• Improved throughput